Dynex offer a range of specifically designed devices for the traction market. The devices provide an efficient source of energy whilst working to high reliability for long periods of time.

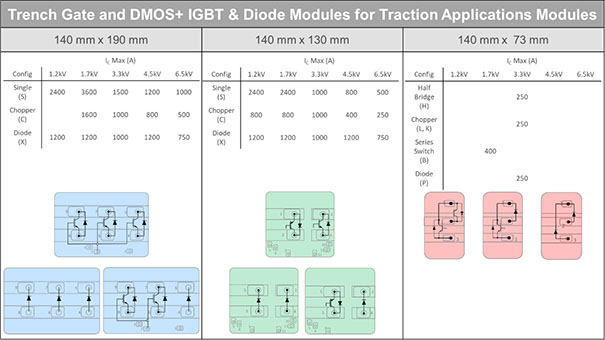

Most importantly among Dynex’s IGBTs is the ability to choose a low Esw,(switching loss optimised) low Vce (conduction loss) or Balanced Losses optimised IGBT.

Refer to AN6156 for power loss estimation of Dynex IGBTs and Dynex Design Tool for web hosted simulator; PLECs models are available for Dynex IGBTs.

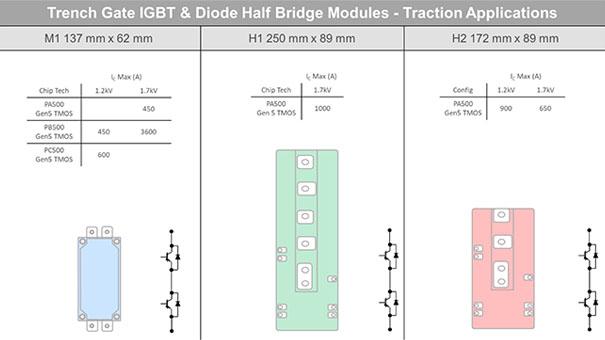

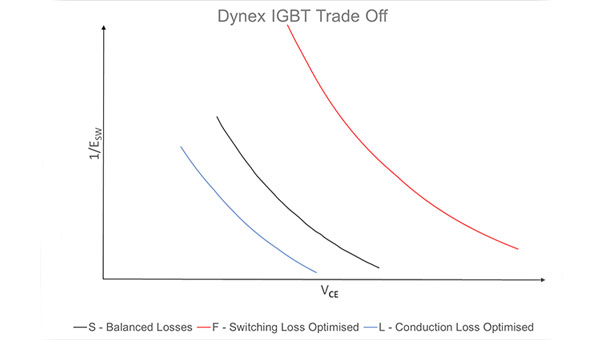

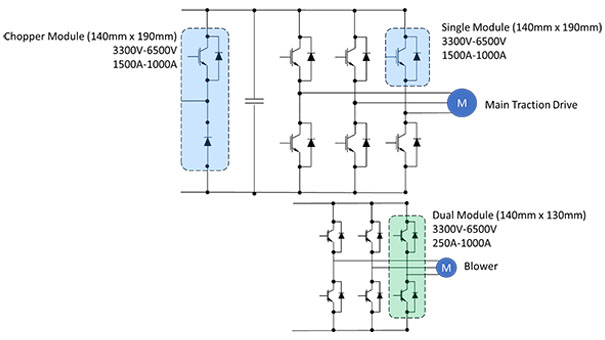

The Dynex range of 1.2kV to 6.5kV IGBT modules are primarily suitable for use in traction applications that require thermal cycling capability. These modules are available in single, half bridge and chopper configurations and are designed in various packages types.

Thermal Management

IGBTs are designed to handle high levels of heat generated during the power conversion process. Their improved thermal stability and ability to operate in high-temperature environments make them suitable for demanding traction applications, where continuous operation is required.

The ability to implement regenerative braking using IGBTs is a significant advantage in traction applications. It saves energy and reduces the wear on mechanical braking systems leading to lower maintenance costs and extended equipment lifespan.

The durability and reliability of IGBTs result in lower maintenance costs and longer intervals between service checks. This is particularly important in rail systems, where downtime can cause significant disruptions.

Figure 1 IGBT Traction Application

Bipolar

The Bipolar range of Gate Turn Off Thyristors ( GTO’s ) 1300V to 4500V are primarily designed for use in railway traction and light rail propulsion drives. The devices are highly reliable, reducing the need for maintenance and replacement throughout their years of service. They have been designed to enable DC turn on and off in a controlled manner.

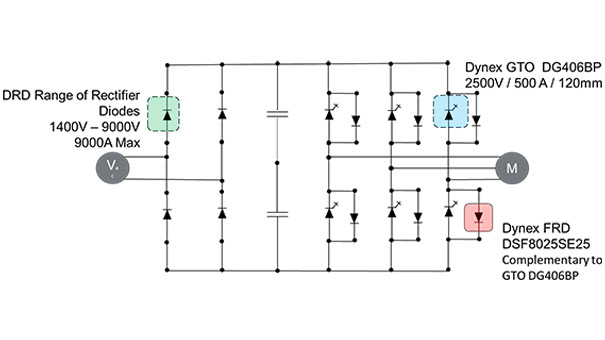

Figure 3 Bipolar Traction Application

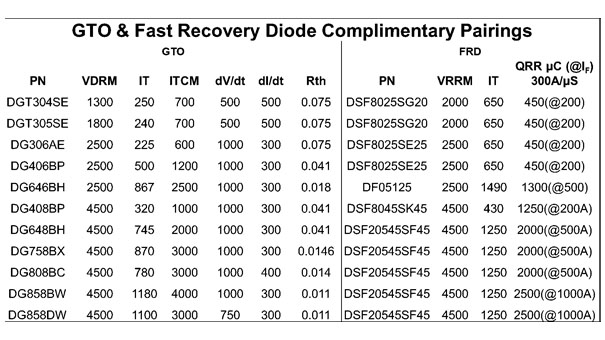

Dynex DSF Range of Fast Recovery Diodes are the ideal combination to be paired with Dynex GTOs for inverter applications. The table below illustrates which FRDs can be utilised with Dynex GTOs. For traction rectification applications Dynex offers our DCR range of Phase Control Thyristors, and DRD range of Rectifier Diodes.

Dynex offers several Application Notes for Bipolar Products.

Figure 4 GTO and FRD Pairing

In addition to our standard and customised semiconductor product offerings, Dynex Power Assemblies team can provide traction converter upgrade and overhaul. Dynex can offer an assessment of the likely health of semiconductors in application, as well as providing a feasibility report on the current availability of equivalent parts available for replacement or spare stock.

Dynex offer the following capabilities to support this; re-traction of propulsion systems, converter mid-life upgrade and overhaul, reliability improvements and replacement Semiconductor devices. The mid-life upgrades offer a number of benefits including; improved reliability and maintainability resulting in reduced life cycle cost, availability through lower downtime and higher reliability and obsolescence management offering full collaborative agreement with Dynex insures long-term UK support for spares and maintenance.

Specific traction applications include; trams, light rail, commuter rail, high speed-rail, transit rail, intercity rail and freight rail.